CANDOCK DRIVE ON BLOCKS FOR BOATS & PERSONAL WATERCRAFT

*This product requires a custom quote based on the desired layout and size. Please contact us for pricing details *

CanDock offers an exceptional solution for effortlessly getting your boat, jet ski, or personal watercraft in and out of the water. Utilizing their patented JETSLIDE, which supports watercraft weighing up to 3,000 lbs, CanDock allows you to create a customized configuration tailored to your specific needs. It's an ideal choice for various watercraft, including fishing boats, PWCs, power catamarans, Craigcats, rigid inflatables, skiffs, flat-bottom boats, kayaks, and canoes.

This versatile system can seamlessly adapt to your home or marina boat slip. Plus, as your watercraft collection grows, you can easily expand the system by adding more blocks. It's the ultimate solution for convenient and flexible watercraft access.

The JetSlide has been meticulously designed to evenly distribute the watercraft's weight, preventing undue pressure on the hull. Lightweight and durable, the JETSLIDE is resistant to impact, chemicals, UV rays, and changing weather conditions. Its foam-filled interior ensures it remains afloat, even in the most challenging conditions.

SHIPPING NOTE: Our website calculates live freight shipping costs. For some of our larger products, we can offer better shipping rates when multiple products are combined into one shipment. If you'd like a custom shipping quote, please sign in or create an account, add the products to your cart, and on the cart page, click the "Request a Quote" link. We will manually check if we can provide a better rate.

KEY FEATURES

- Effortless On & Off Loading for Boats

- Supports up to 3,000 lbs

- Blocks and Connecting Pins available in Gray or Beige

- Up to 4 Connecting Points Per Block

- High-Density Polyethylene construction is impact and perforation-resistant, with no sharp edges

- Environmentally friendly and 100% recyclable, non-polluting, rot-proof, splinter-proof, and rust-proof

- Requires minimal to no maintenance and easy removal for cleaning

- Cube design supports 150 lbs per Full Cube

ADDITIONAL COMPONENTS

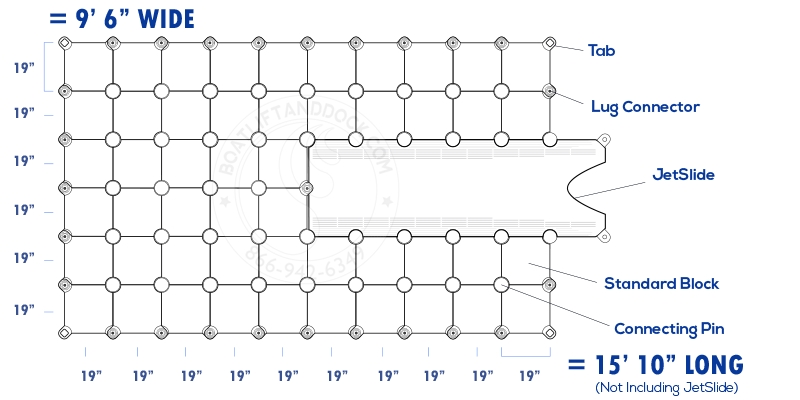

When planning your drive-on boat platform, your layout choice dictates the parts needed. Opting for a JetSlide is optional and determined by the watercraft you are looking to park on the platform. For flat-bottom boats, kayaks and canoes, you can lower the first row of cubes by filling them with water and creating a ramp. This also works well for the Craigcats. You can view the main components below:

JetSlide - Measures 114 inches in length, 38" in width, and stands at 15" in height, weighing 150 lbs. Constructed from high-density polyethylene and featuring a foam-filled interior, this Dry Dock system enables you to effortlessly dry dock your boat without requiring mechanical assistance, unlike systems with movable parts prone to damage, such as rollers that can seize in saltwater environments.

G2 Cube or Standard Block - Measures 19 inches in length and width and has a height of 14 inches. The design incorporates four tabs, each situated at different heights. When these tabs are aligned correctly, they form a flawless configuration. The tabs are sequentially numbered from 1 to 4 and intended to overlap in this specific order. Once they are perfectly aligned, a threaded pin is employed to fasten them together securely.

G2 Low Profile Cube - This cube measures 19 inches in length and width and has a height of 9 inches. These are designed to reduce the average freeboard to 7 inches, compared to the 12 inches of our standard G2 cubes. They offer the same functionalities but with a lower freeboard and can be used to create a ramp into the water.

Connecting Pin - These threaded pins serve the crucial function of linking the blocks together and attaching them to the JetSlide. Each pin features two notches at the top, designed for the use of a tool to secure the pin firmly in place. The assembly tool, specifically designed to work with these notches, simplifies tasks like installation, removal, or modification.

Sliding Nut - The sliding nuts are important and specifically designed for use on the lowest tab, usually number one. These nuts provide the necessary female thread connection for the connecting pin. To ensure a secure and precise fit, the nut is designed to slide onto the tab, perfectly positioning the threads on the underside of the tab.

Spacers - The spacers are required where less than four tabs are coming together. They effectively fill the gaps, ensuring the assembly remains square and secure. For instance, if you're working with only two tabs, two spacers would be utilized to compensate for the missing tabs.

Lug Bolt & Nut - These connectors are designed for use along the outer perimeter of the dock layout and enable the blocks to be attached securely where a pin cannot be used. The lug and nut can be used directly when the tabs are stacked with no gaps. However, adding spacers becomes necessary for a tight fit if there are gaps between the tabs. While lug connectors are not mandatory in every assembly, their use is highly recommended to enhance the stability and durability of the dock structure.

HOW TO DETERMINE YOUR NEEDS

The easiest way to design your drive-on platform is to start with the overall length and width of your boat. Divide the length of your boat in inches by 19" to determine the number of blocks needed for length, accounting for the JetSlide (if being used) in the center. Repeat the process for the width to determine the number of blocks needed for width. Multiply the length and width blocks to get the total number needed for your platform.

CANDOCK ANCHORING

Correctly anchoring your floating dock is crucial for maintaining its stability and position. Without proper anchoring, docks can drift due to currents, wind, or boat wakes, leading to potential damage to the dock itself, boats moored to it, or nearby structures. Below we discuss the different options for anchoring CanDock Drive On Platforms.

Post & Piling - Using posts or pilings for anchoring a floating dock is a time-tested and dependable method. Selecting the appropriate size of the post or pile is crucial and depends on the location of the installation. For posts with a diameter of up to 4 inches, anchoring Cubes are an effective solution. There are specially designed brackets for bigger pilings that can be easily attached to the CanDock, ensuring a secure and stable anchoring system.

Struts & Stiffarms - This anchoring method uses aluminum extrusions and brackets, which are affixed both to shore and to the dock. This setup establishes a fixed distance from the shore, effectively securing the dock in position. To enhance stability and maintain the structure's integrity, cables are typically arranged in an X pattern between the struts or arms. This technique is particularly suitable for docks situated near the shore, especially in situations where using posts or pilings is impractical due to deep waters or soft lakebeds.

Dead Weight - This method involves using heavy weights, typically made of concrete, which are placed on the lake or seabed. These weights are connected to the dock through chains, cables and/or ropes. The gravitational pull ensures the dock remains anchored in its designated spot, countering water movements and wind. Brackets that attach to the CanDock without damaging the cubes are available and provide the necessary connection point and strength needed to hold the dock in place.

H-Beam Sliders - This anchoring method employs a vertically mounted I-Beam and a specialized bracket. The bracket, fitted to the I-Beam, features rollers that enable it to move up and down without any resistance. The other part of the bracket is secured to the dock, allowing it to easily adjust to variations in waves, tides, or water levels. However, this configuration ensures the dock remains firmly in its designated position without drifting. This system is particularly effective in locations where water levels fluctuate regularly, providing a stable and adaptable anchoring solution.

Direct Connect - A direct connection is suitable when linking to another floating system or in areas with stable water levels. However, it's rare to find locations where water levels remain constant, so we generally advise using direct connections only with other floating structures. This approach ensures synchronized movement, preventing stress or binding. Conversely, directly attaching a floating dock to a fixed structure can lead to issues, even with minor water level changes. Therefore, this method is best reserved for scenarios where both connected systems can move harmoniously with the water's ups and downs.

The CanDock system is thoughtfully engineered to prioritize environmental protection and sustainability. Constructed from materials that are not only non-toxic but also fully recyclable, the system reflects a commitment to reducing its ecological footprint. This eco-conscious approach extends to its design, which ensures a generous allowance for water circulation beneath the structure. Such a feature is crucial for mitigating the dock's impact on the aquatic ecosystem, helping to preserve the natural habitat for marine life. Additionally, this continuous water flow plays a vital role in upholding the purity and quality of the water, demonstrating CanDock's dedication to maintaining the health of our waterways for future generations.

ADDITIONAL INFORMATION

- Complete Drive On systems ship via common carrier freight.

- Please contact us for estimates on large, complex, or multi-unit layouts